Smart Factory One-Stop Service

Apply ICT, which combines digital automation solutions to the production process,

such as design, development, manufacturing and distribution, and logistics, to provide

intelligent production plant construction service that improves productivity, quality

and customer satisfaction

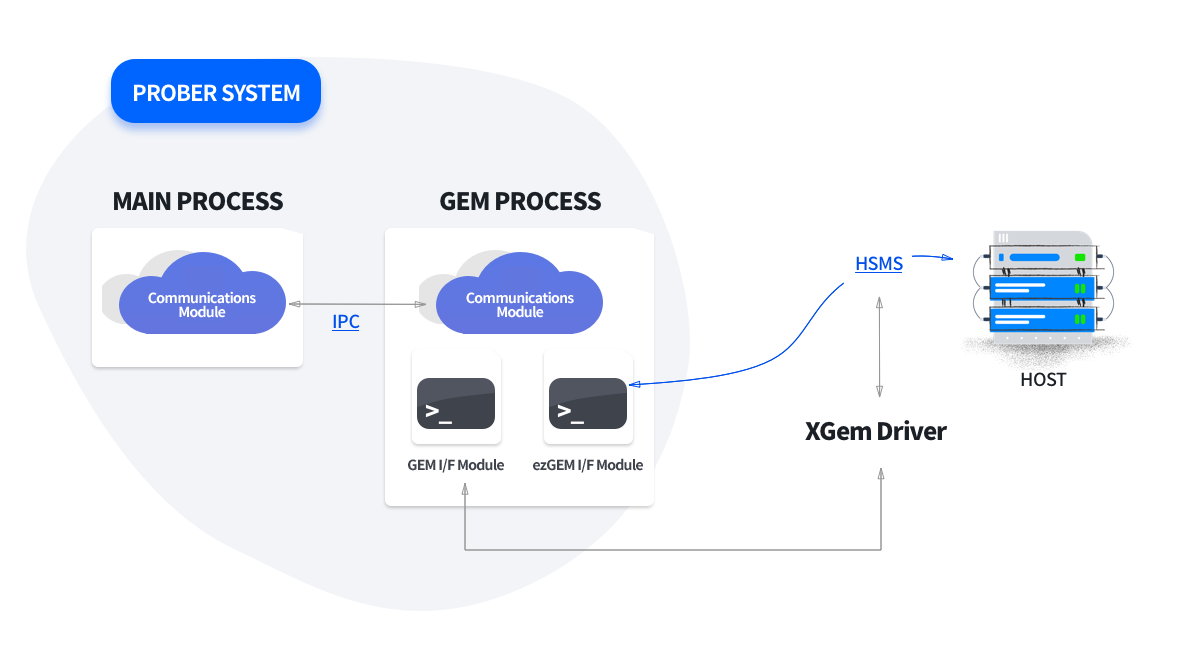

Building the GEM Process

The GEM module is built by separating the control, inspection, analysis,

and communication modules of the equipment from the traditional method of

running in one main software into a separate process to improve the performance

of the main software and to improve the software management efficiency of the maintenance, etc.

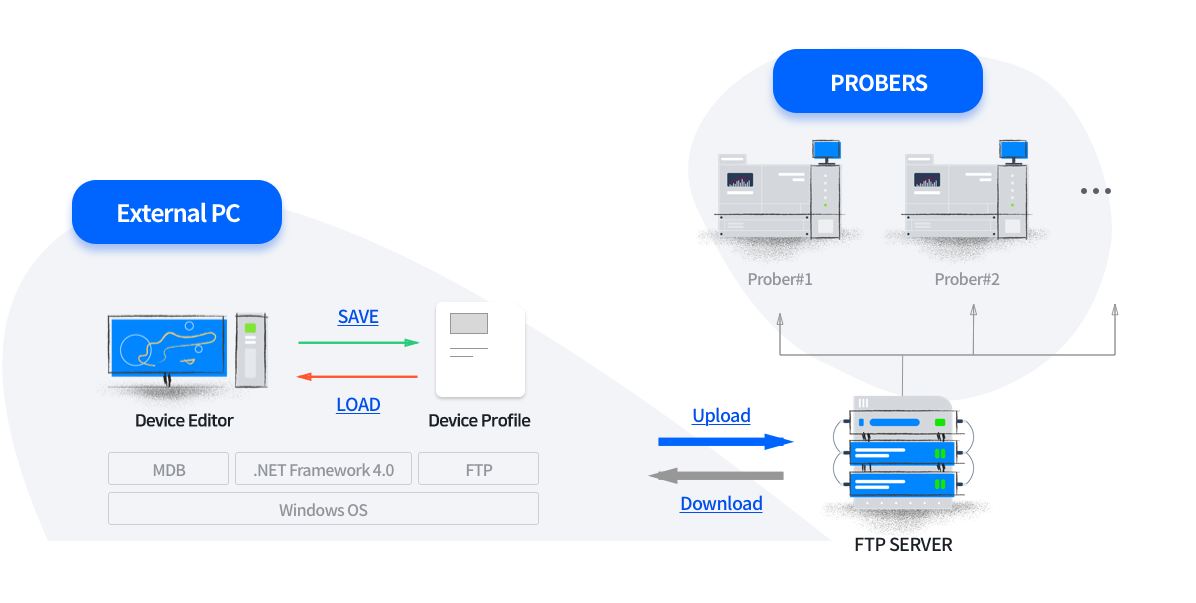

Building the Recipe Editor System

To improve the existing environment where actual equipment needs to be moved to analyze and

manipulate the parameters of the equipment, a system that can analyze and manipulate parameters

outside the equipment is established to improve spatial constraints and ease of operation.

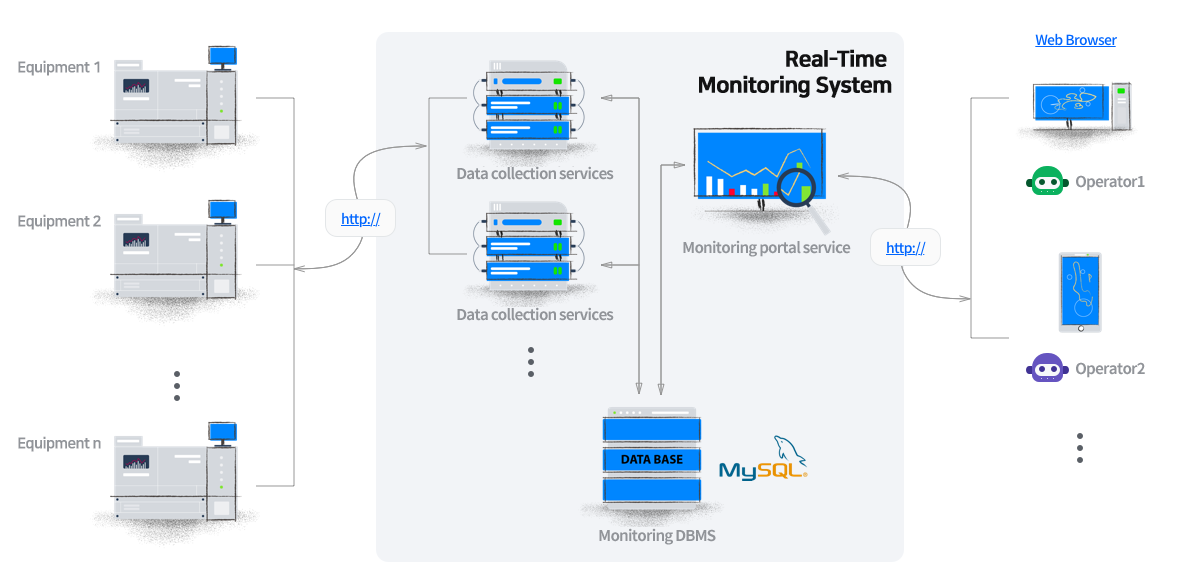

Building the Real-time monitoring system

Real-Time Monitoring System, which enables real-time monitoring of equipment

in line at remote locations, is established to reduce human, physical and temporal

consumption to ensure productivity and operational efficiency.